FAQs

During most component manufacturing processes, contaminants in the form of lubricants, polishing soaps, cutting fluids etc. are introduced to facilitate the activity being undertaken. On completion of the activity, these contaminants need to be removed from the item, either to allow the next stage of the process to be carried out, or to ensure that they are in an acceptable condition to be supplied to the end user. The complexity of the cleaning process will depend not only on the nature and amount of the contaminant but also the standard of cleanliness required. Thus, a process to remove unwanted stains to ensure a cosmetically clean surface may be fundamentally different to one removing contaminants that affect the operation or functionality of a product.

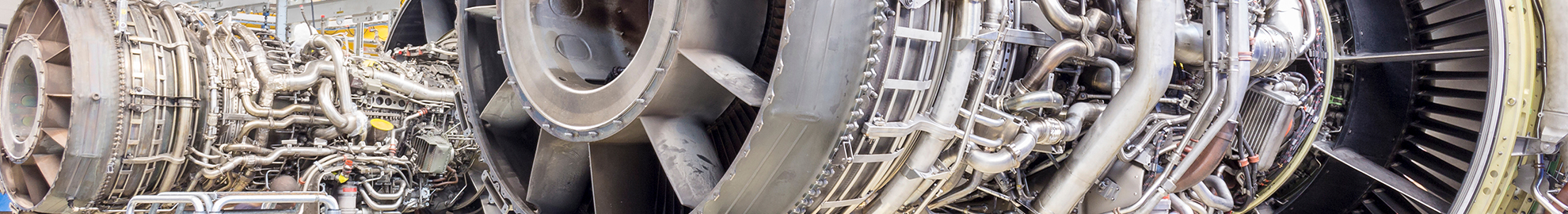

In some manufacturing sectors, cleaning specifications have been established that have taken account of the various factors considered when determining the cleanliness of a surface (See How Clean is ‘Clean’?). These specifications provide detailed information on the type of cleaning process to be used, including the approved chemicals, process conditions and cleaning times to ensure an acceptable standard of cleanliness is obtained. Such specifications are common in many sectors of industry, including aerospace and medical equipment.

This is a simple question but the answer can be more complex. Establishing what is an acceptable standard of cleanliness needs to take into account factors such as the application and the required functionality of the part. In a maintenance cleaning environment, or where it is necessary to clean a part between manufacturing stages, ‘clean’ may simply mean removal of the specific contaminant to such an extent as to facilitate further working of the part. By contrast, a surgical implant, or a printed circuit board that forms part of a missile guidance system must be cleaned to a much higher standard. Thus, determining what is ‘clean’ will involve some form of assessment and comparison with an established pass/fail criterion. Assessment methods can be of two, basic types: 1. Qualitative methods e.g. visual inspection, which may include wiping to look for a visible residue. 2. Quantitative methods e.g. measuring contamination using established surface analysis techniques.

Cleaning involves the removal of a contaminant from the surface of a component. In determining the most suitable process for a particular application, it is important to consider a number of factors: 1. The nature of the component e.g. the materials of construction, its geometry, whether it is susceptible to corrosion etc. 2. The nature of the contaminant e.g. whether it is organic or inorganic, polar or non-polar, liquid or solid, soluble or insoluble. 3. The impact of previous working on the contaminant e.g. whether its nature has changed due to temperature or pressure, whether it is fresh or has aged or hardened. There is no definitive answer to which process is best, since they all can achieve similar standards of cleanliness across the vast majority of applications. All three processes offer advantages and disadvantages: Solvents are generally considered to be hazardous chemicals, but cleaning processes are generally quick, simple and effective. Aqueous and semi-aqueous cleaning chemicals are considered to have advantages from a health and safety perspective, but cleaning processes are generally more complex and slower. All three technologies impact on the environment. Aqueous impacts in terms of energy and water consumption, and effluent disposal, whilst the environmental impact of solvents relate to their initial manufacture, release to atmosphere during use, and disposal of waste. By the correct selection of process and equipment, it is possible to utilise the advantages of each technology whilst effectively managing the potential disadvantages.

Pre-treatment is the term applied to the process of preparing a metal surface for painting, powder coating or electroplating. This surface preparation process generally involves three, basic treatments: 1. Degreasing the metal surface to remove contaminants, 2. De-rusting to remove corrosion products, usually using acids. 3. Applying a conversion coating e.g. phosphating to protect the metal surface. After each of the above treatments, thorough rinsing of the metal surfaces is required to prevent carry-over and cross-contamination. Thus, in practice, effective pre-treatment can involve multiple process stages with automated workload handling.

Ultrasonic cleaning utilises high-frequency sound waves to create mechanical agitation within the cleaning medium to produce a versatile, high-performance cleaning process effective on a wide range of contaminants and substrates. Ultrasonic waves are mechanical pressure waves generated when high frequency, high voltage, current is applied to ultrasonic transducers. Ultrasonic waves interact with the irradiated liquid to create tiny bubbles of vapour, which grow to a maximum size (related to the frequency of ultrasonics used) and then implode, releasing energy. The energy released from an implosion close to the surface of the component fragments or disintegrates the contaminant and the generated pressure wave carries the fragments away from the surface. The energy released by the implosions can penetrate deep into crevices, blind holes and other, generally inaccessible areas to produce a consistent, uniform cleaning effect on even the most complex components.

Aqueous cleaning is a process that uses a solution of detergent in water to remove organic and inorganic contaminants from an item. Detergents can be complex formulations containing a number of components, each having a specific function but, in simple terms, they fall into two, basic categories: 1. Those that chemically react with organic contaminants, converting them into water-soluble products. 2. Those that emulsify the organic contaminant with water. Within each of these broad categories, detergents encompass a wide range of chemical types and so it is important to match their chemistries with the nature of the substrate and the contaminants to be removed. Cleaning is normally carried out at elevated temperature to increase the rate of chemical reaction. This is further enhanced by mechanical action, usually in the form of spraying, either in air or under immersion, ultrasonic irradiation of the liquid, or agitation of the workload within the liquid. The type of mechanical action utilised depends on the type of detergent, the geometry of the items to be cleaned and the standard of cleanliness required. Furthermore, depending on the type of detergent, and the standard of cleanliness required, it may be necessary to follow the wash stage by one or more rinses in water, which may be purified. If completely dry components are required, it may also be necessary to include a hot-air drying stage.

This is a term normally applied to aqueous cleaning equipment utilising brush, spray or immersion cleaning (either individually or in combination). Parts washers can be of three, general types: 1. Manual equipment comprising a simple work station providing brush, spray and immersion cleaning. Cleaning is generally achieved using a combination of the chemical action of the solution and mechanical action provided by the brush. 2. Automated spray equipment. This is a cabinet with a lid that is raised to allow components to be introduced onto a rotating work basket. Wash solution is applied to the items via spray bars above and below the work basket and cleaning is achieved using a combination of the chemical action of the solution and mechanical action provided by the sprays. The cleaning solution can be heated to assist with cleaning. 3. Automated immersion equipment. This is an open tank with lift-up lid to allow work to be introduced. Wash solution is contained within the tank and workloads are introduced onto a pneumatically operated platform located above the solution. When the process is initiated, the workload is lowered into the solution and then agitated up and down to provide mechanical assistance to the chemical action of the solution. The wash solution can be heated to assist the cleaning action of the solution.

The semi-aqueous cleaning process incorporates an organic medium to clean components and then water as the rinse medium. It, theoretically, utilises the specific cleaning benefits of both solvent and aqueous cleaning to effectively remove both organic and inorganic contaminants. The organic wash solution becomes progressively contaminated with use and so must be periodically replaced with fresh solution. The rinse water is also continuously purified to remove the organic component. The cleaning process normally utilises liquid immersion cleaning with either spray under immersion or ultrasonic agitation.

Bioremediation is the process by which microorganisms are used to break down contaminants, such as oils and light greases, into non-hazardous products such as carbon dioxide and water. The microorganisms can be either naturally occurring or deliberately introduced into the process, as is the case with the 'Biozone' parts washing system.

Vapour degreasing has become a generic term used for any cleaning process that uses a hot solvent as the cleaning medium. However, more accurately, it is the simplest, and traditionally, the most commonly used, solvent cleaning process. True vapour degreasing uses the vapour generated when a solvent, such as perchloroethylene, is heated to its boiling point. When the hot vapour encounters an item at a lower temperature, such as a component to be cleaned, it condenses and runs down the surface, dissolving any contamination it comes into contact with. The latent heat released when the vapour condenses gradually heats up the item until it reaches the same temperature as the vapour, at which point, condensing, and thus cleaning, stops. When the component is removed from the solvent vapour, the heat retained by the item evaporates the thin film of liquid solvent, leaving the part clean and dry. Vapour degreasing is simple, fast and effective for cleaning items with simple geometry and relatively high thermal mass. It is not so effective on complex items with blind holes, cavities etc., or on items that heat up very quickly e.g. thin aluminium sheet. In these instances, cleaning by immersion into liquid solvent, either at the boiling point or irradiated with ultrasonic energy, is a more effective cleaning process.

The term derives from European Standard EN12921, which defines cleaning equipment suitable for use with non-flammable solvents. Within the six equipment types identified within the standard, Types III, IV and V are termed 'closed' and relate to machines where cleaning, rinsing and drying is undertaken in a single, sealed chamber that cannot be accessed until the process cycle has been completed. Closed machines incorporate integral carbon abatement and generally operate without the need for an external vent to atmosphere (See Table below)

The term derives from European Standard EN12921, which defines cleaning equipment suitable for use with non-flammable solvents. Within the six equipment types identified within the standard, Types II, and III are termed 'enclosed' and relate to machines where a conventional solvent cleaning process is contained within an enclosure that isolates the process from the machine operator. Enclosed machines offer a higher level of process containment than traditional, open-topped equipment (defined as Type I in the standard) but a slightly lower level of containment than 'closed' machines (See Table below):

The term comes from a German Federal Government Directive, known as the 'VbF' Directive, which classifies solvents according to their flashpoint. Class A3 solvents have a flashpoint in the range 55-100C and include isoparaffins and modified alcohols (alkoxy propanol). These chemicals have excellent solvency but must be used in specially designed equipment working under vacuum in order to suppress their flammability.

Hydrofluoroethers (HFEs) and hydrofluorocarbons (HFCs) are two families of halogenated solvents that have found increasing application as alternatives to the traditional cleaning solvents such as trichloroethylene. Both are non-flammable, have low toxicity, and can be used as cleaning solvents in their own right, or in blends with other chemicals that improve, or modify, their solvency. Although significantly more expensive than the traditional solvents, their properties are such that, when used in correctly designed equipment, losses are generally low, making running costs comparable to traditional solvent processes.

Mono-solvent cleaning is simply a cleaning process where a single solvent is used in the cleaning equipment. Traditional vapour degreasing is a mono-solvent cleaning process, although it is not generally referred to as such. Indeed, the term has only really come into general use with the introduction of HFE and HFC solvents as cleaning agents and is used to describe a cleaning process that uses a solvent formulation comprising a HFE, or HFC, blended with other chemical constituents.

Co-solvent cleaning is the term applied to a cleaning process where a HFE or HFC is used in conjunction with another chemical, known as the 'solvating agent', to provide enhanced cleaning performance. A co-solvent cleaning process usually involves two stages: 1. Cleaning in a mixture of the solvating agent and HFE/HFC (typically in a ratio of 60% solvating agent + 40% HFE/HFC. 2. Rinsing in pure HFE/HFC to remove traces of the solvating agent. The process is used for applications where either a high soil loading is anticipated, or where a higher operating temperature is required than can be provided by using the HFE/HFC alone. Hydrocarbons are commonly used as solvating agents because they have good solvency.